ESG - Environmental, Social and Governance

Cablenet, an industry-leading computer and network cabling supplier, has pledged to bec

Cablenet, an industry-leading computer and network cabling supplier, has pledged to bec

Eighteen months ago, we decided to amend the specification of all our Category 6 and C

From first starting her career with us in 1999 at our original offices in Twickenham, t

We're excited to announce Rickie's return to the Cablenet team. After a 14-year

In May of 1979, I embarked on my entrepreneurial adventure, diving headfirst into the w

Welcome to our exclusive Cabinet Guide, designed to be your compass in the (sometimes)

Today, millions of people globally depend on Ethernet. One of the world’s most durabl

The need for reliable power, monitoring, and intelligence has never been greater.

Please see below for detailed information regarding our opening hours.

EZ-Path is a range of mechanical devices that provide fully compliant fire-stopping for

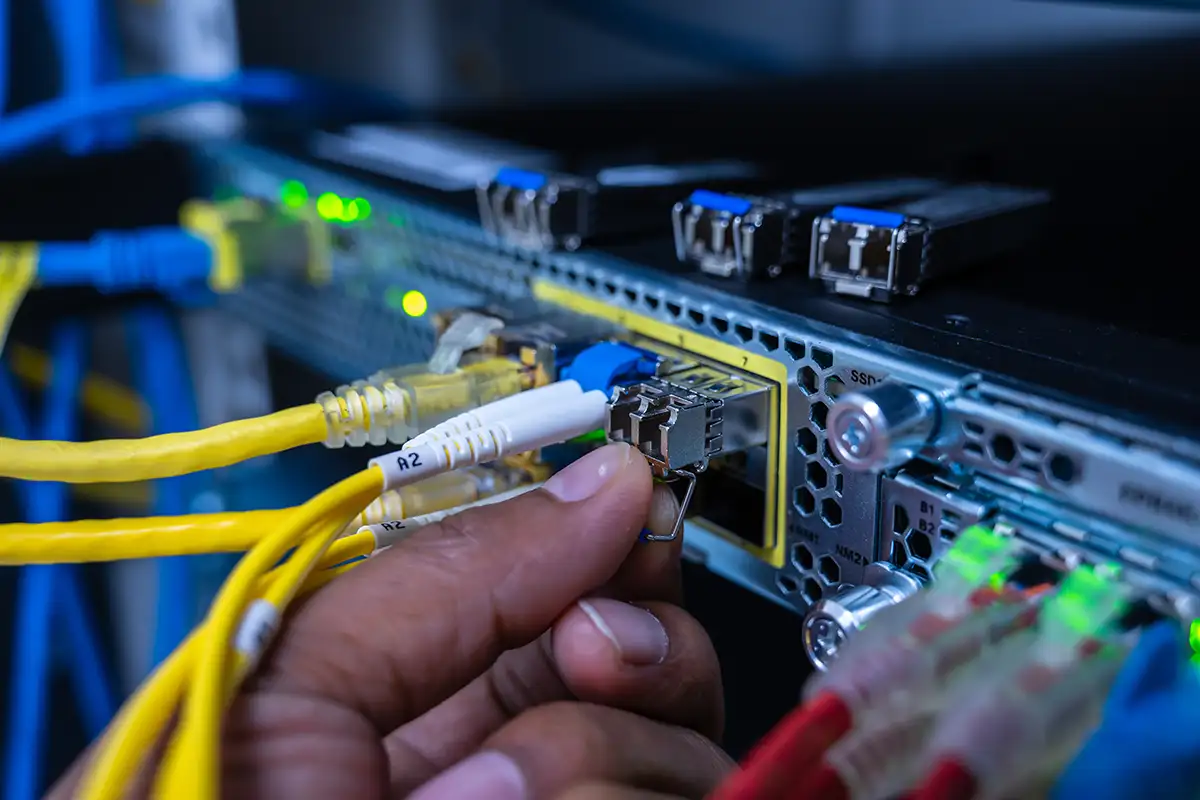

Discover more about the different types of SFP available and some of their features.

Our New Tech Terms Guide has been enhanced to support all the products we sell and feat